A wide variety of materials, including carbon and stainless steel, as well as numerous exotic and unique alloys, are used in the design and production of a broad range of static mixers by Altam Manufacturing. In Los Angeles, California

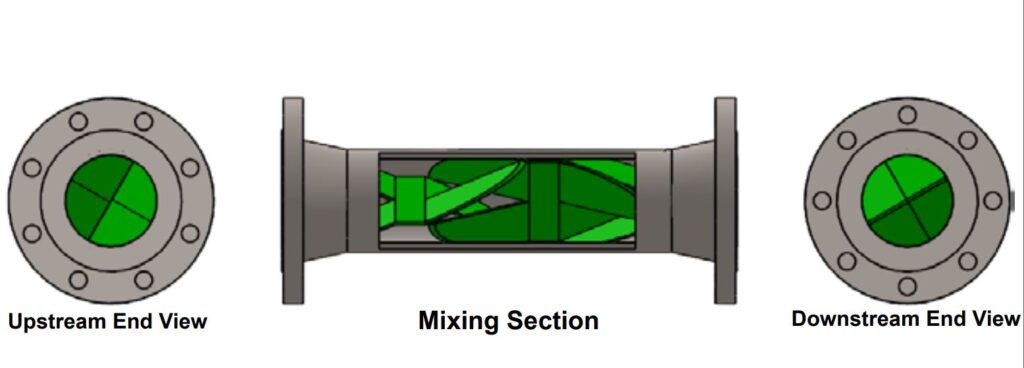

The Type “CM” Custody Transfer Mixers employ a simple design to provide the ultimate in mixing. Each unit achieves high mixing efficiency through multiple-action mixing. The crude oil and water content are mixed through equal division, re-division and rotational mixing which enhances turbulence and mixing. This results in complete uniformly mixed product at the outlet. The “CM” Custody Transfer Mixer is used when accurate sampling is required such as in the custody transfer of crude oil from either ship to shore or storage facility to another. The design flexibility of MXR’s Mixing Technologies will provide superior mixing performance in Custody Transfer Applications. Standard Material of construction is Carbon Steel. Available in pipe sizes from 3/4″ to 60″ diameter.

Application

Application

• Provide homogenization of bottom sediment and water prior to sampling in

Custody Transfer pipelines.

• Mixing of oil streams such as water cut measurement, online sampling of

hydrocarbons, and spot sampling or automatic grab sample.

Benefits

• Low cost

• Short mixing length

• Guaranteed mixing performance

• Available in stock for immediate shipment

• Very high mixing efficiency for accurate sampling

Design

• Highly effective in mixing liquid/liquid or gas/liquid dispersion.

• To meet the stringent requirements of ISO 3171, API 8.2, and ASTM D4177.

Installation

• Can be installed in a horizontal or vertical pipeline.

• Automatic sampler to be located around three to five pipe diameters of

straight pipe downstream of the static mixer.

The Type “CO-M” Condensate Mixer is a very high heating efficiency device (up to 99%) due to direct mixing of condensates into the process line. No moving parts, low capital cost, minimize noise and vibration and practically no annual maintenance cost required. Typical Condensate Mixing application includes Chemical/Petro-Chemical Plants, Oil Refineries, and Power Plants. The design flexibility of MXR’s Condensate Mixing Technologies will provide superior heating performance in any fluid mixing application. Standard Material of construction is Type 316/L Stainless Steel. Available in pipe sizes from 1″ to 36″ diameter.

Industrial Applications

A wide variety of industrial process applications take advantage of condensate mixing technology including:

– Chemical & Petro-Chemical

– Oil Refineries

– Power Plants

The Type “DE” Desuperheater is custom-engineered for direct injection of water vapor in the form of uniform water droplets into a line containing superheated steam. Allows replacement of the spray nozzle without removing the desuperheater from the line. Each unit employs 2 specially designed mixing modules to instantaneously mix the water mist with the superheated steam in a mixing chamber. Typical desuperheater application includes Power Generation, Process Industries, Paper and Board Industry, Food Industry, Chemical & Pharmaceutical, Oil & Gas, Brewing & Distilling, Boiler & Turbine installation. The design flexibility of MXR’s Desuperheating Technologies will provide superior cooling performance in any steam desuperheating application. Standard Material of construction is Type 316/L Stainless Steel. Available in pipe sizes from 3″ to 60″ diameter.

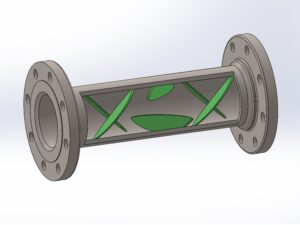

The “EA” Mixing Element Assembly is a series of custom-engineered left-right-left configuration welded together as an assembly designed to fit into existing/new spool pieces supplied by customer. Unit can be manufactured to be welded inside the pipe or can be removable as an assembly. A removable element assembly will be supplied with an extractor bar and installation instructions.

DESIGN FEATURES & BENEFITS:

Typical Applications

– Water Treatment – Mixing additives like coagulants, flocculants, dewatering agents and for pH control.

– Power Plants – Introducing and mixing gaseous additives such as ammonia for NOx reduction.

High Mixing Efficiency

– High Mixing Efficiency for Liquid-Liquid, Liquid-Gas & Gas-Gas Mixing Application.

– About 50-70% lower than conventional Static Mixers available in market today.

Short Mixing Length

– Typical Length required is just 2 to 4 times Nominal Pipe Diameter.

Option – Port/Injector

– Better distribution of Additives prior to the Static Mixer.

– More efficient mixing as a result.

Materials Of Construction

– Carbon Steel, Stainless Steel, Titanium and other exotic metals.

– FRP, PVC, CPVC, PVDF and other Thermoplastics.

Process Applications

A wide variety of process applications take advantage of static mixing technology including:

Turbulent Flow Flow

– Gas – Liquid Contacting

– Gas Mixing Low Viscosity Liquids Mixing

Chemical Industry

– Dispersing immiscible liquids in washing and extraction operations

– Dissolve gases into liquids such as NH3, SO2, Cl2

– Mix gases with air in front of catalytic reactors such as in the production of Nitric Acid

– Mix Reactive materials in short length

Water & Wastewater Treatment

– Dissolving CO2, O2, Cl2, ozone into water

– Flocculants dilution and addition to waste water

– Mix ground and surface waters

– pH control of waste water with acids/bases

The standard Type “N” Static Mixers employ a simple design to provide the ultimate in mixing. Each unit achieves high mixing efficiency through multiple-action mixing. The liquid and additives are injected upstream of the static mixer are mixed through equal division, re-division, and rotational mixing which enchances turbulence and mixing. The “N” Static Mixer solves the problem when mixing of two or more liquids is required. Typical mixing application includes mixing water or chemicals in Water and Wastewater Treatment Plants, Chemical Plants, Oil Refineries, Oil & Gas Plants, Food Processing, Pulp & Paper Mills. The design flexibility of MXR’s Mixing Technologies will provide superior mixing performance in any liquid, gas, slurry, or particulate mixing. Standard Material of construction is Carbon Steel. Available in pipe sizes from 3/4″ to 48″ diameter.

The standard Type “P” Static Mixers includes a side port for the introduction of an additive or chemicals to be mixed, units have no moving parts, and employ a simple design to provide the ultimate in mixing. Each unit achieves high mixing efficiency through multiple-action mixing. The liquid and additives are mixed through equal division, re-division, and rotational mixing to enhance turbulence and mixing. The “P” Static Mixer solves the problem when mixing of two or more liquids is required. The design flexibility of MXR’s Mixing Technologies will provide superior mixing performance in any liquid, gas, slurry, or particulate mixing. Standard Material of construction is Carbon Steel. Available in pipe sizes from 3/4″ to 48″ diameter. Typical mixing application includes mixing water or chemicals in Water and Wastewater Treatment Plants, Chemical Plants, Oil Refineries, Oil & Gas Plants, Food Processing, Pulp & Paper Mills.

The Type “SH” Steam Heater is a very high heating efficiency device (up to 99%) due to direct steam injection into the process line. No moving parts, low capital cost, minimize noise and vibration and practically no annual maintenance cost required. Using a single modulating steam control valve, the Type “SH” Steam Heater could provide up to 10:1 turndown capability. Typical Steam Heating application includes direct injection of steam into water line to produce hot water in Chemical Plants, Oil Refineries, Oil & Gas Plants, Food Processing, Mining, Pulp & Paper Mills for the heating of paper pulp flow steams. The design flexibility of MXR’s Steam Heating Technologies will provide superior heating performance in any fluid heating application. Standard Material of construction is Type 316/L Stainless Steel. Available in pipe sizes from 1″ to 36″ diameter.

Typical Mixing application includes mixing Tomato paste, Ketchup, Condiments, Jams, Jellies, Yogurt, Dairy Products, Soft Drinks & Juices. Type “SM” polished mixing units have no moving parts and will create a very high degree of mixing in a short length. This results in complete uniformly mixed product at the outlet. The design flexibility of MXR’s Mixing Technologies will provide superior mixing performance in any food, beverage, or pharmaceutical mixing application.

The Type “TH” Tank Heater is custom-engineered for direct injection of steam into a tank containing water/liquid. No moving parts, no noise, and no vibration. Each unit employs 2 specially designed mixing modules to equally disperse the steam inside the tank. Typical Steam Heating application includes direct injection of steam into the tank to produce hot water in Chemical Plants, Oil Refineries, Oil & Gas Plants, Food Processing, Mining, Pulp & Paper Mills for heating process water. The design flexibility of MXR’s Tank Heating Technologies will provide superior heating performance in any tank heating application. Standard Material of construction is Type 316/L Stainless Steel. Available in pipe sizes from 2″ to 12″ diameter.

Tank Heating Applications & Industries

General Applications – Water Heating

– Boiler Feedwater

– Central Hot Water

– Hose Stations

– Tank Heating

– Clean-In-Place (CIP)

– Jacketed Vessels/Reactors

A wide variety of process applications take advantage of static mixing technology including: